The food production industry has extremely high requirements for hardware in terms of "hygiene without blind spots" and "durability," especially for the gummy candy company that serves Sam's Club globally. This company previously used stainless steel shoe cabinets from other suppliers, which had several quality issues.

Recently, we upgraded their system: adding two layers to the old shoe cabinets and comprehensively optimizing quality, achieving a double leap forward. This article will compare the core differences between the old and new shoe cabinets, showcasing our craftsmanship.

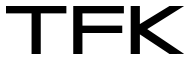

I. Door Edge Sealing: From "Hygiene Dead Spots" to "Seamless Cleanliness"

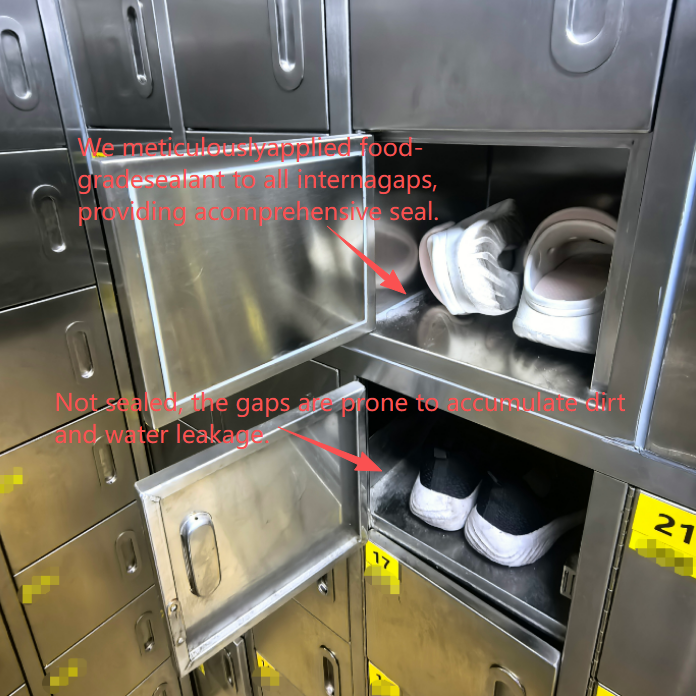

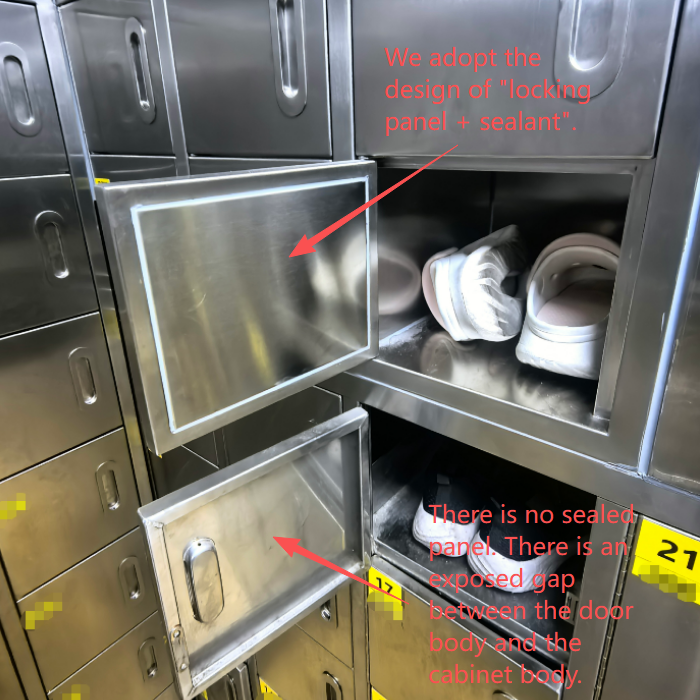

The old shoe cabinet doors lacked edge sealing panels, leaving exposed gaps between the doors and the cabinet body. These gaps easily accumulated dust and candy scraps, creating difficult-to-clean hygiene dead spots that seriously affected workshop hygiene management.

We adopted a "snap-on panel + sealant" design. Custom-made snap-on panels were added to the door edges to cover the gaps, and professional sealant was applied. This completely eliminates dirt accumulation; cleaning only requires wiping the surface, fully meeting food industry hygiene standards.

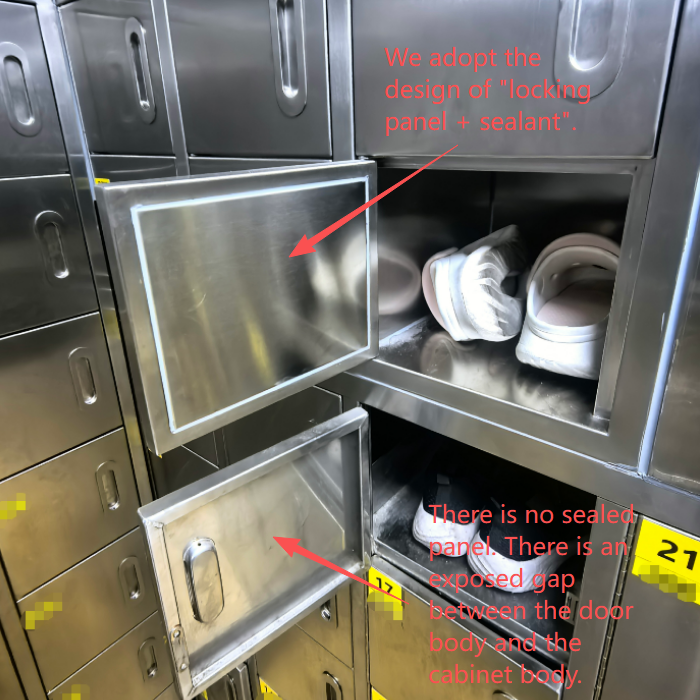

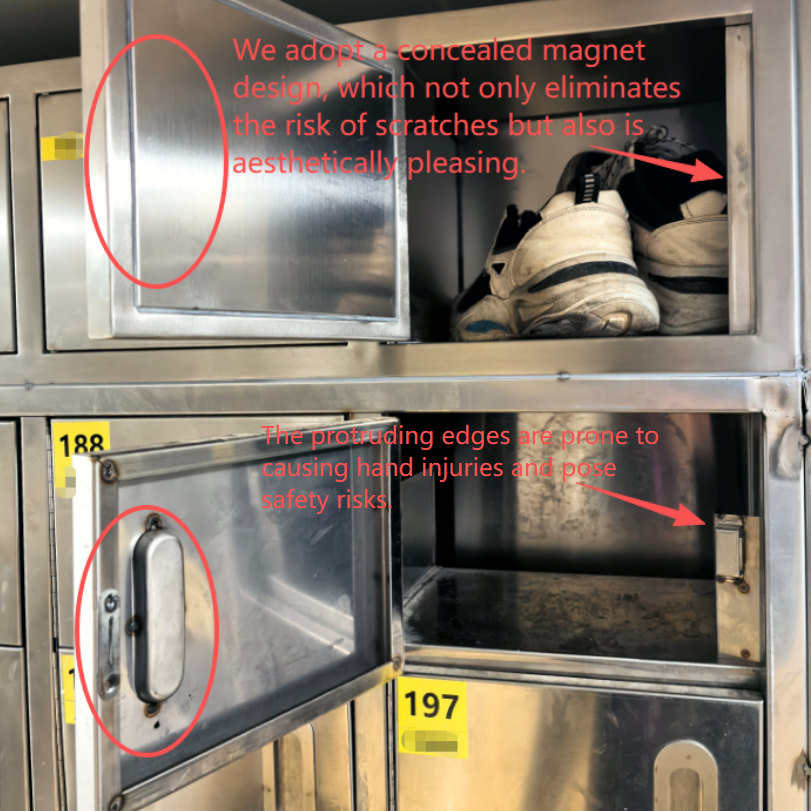

II. Magnet Installation: From "Safety Hazards" to "Invisible Aesthetics"

Old shoe cabinets used exposed magnets, with protruding edges that could scratch hands, posing a safety hazard and clashing with the cabinet's appearance.

We adopted a concealed magnet design, embedding the magnets inside the door for a tight closure. This eliminates the risk of scratching hands and maintains a smooth, aesthetically pleasing door surface, fitting into a clean workshop environment.

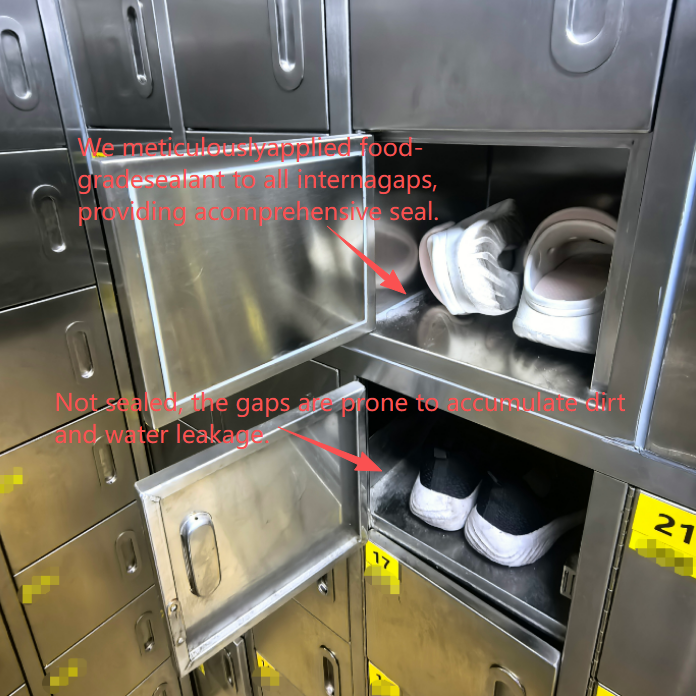

III. Internal Gaps: From "Soil Accumulation and Leaks" to "Full Sealing Protection"

The internal joints of old shoe cabinets were not sealed, allowing dirt and water to accumulate and potentially causing corrosion, shortening the cabinet's lifespan.

We meticulously applied food-grade sealant to all internal gaps, providing a comprehensive seal. This is waterproof, moisture-proof, and stain-resistant, extending the cabinet's lifespan and improving cleaning efficiency.

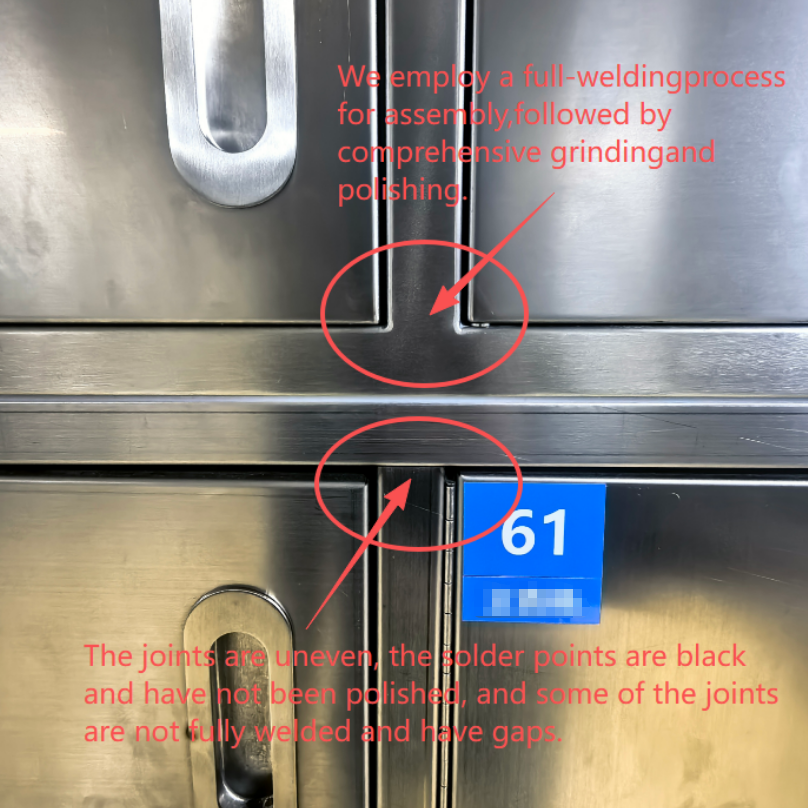

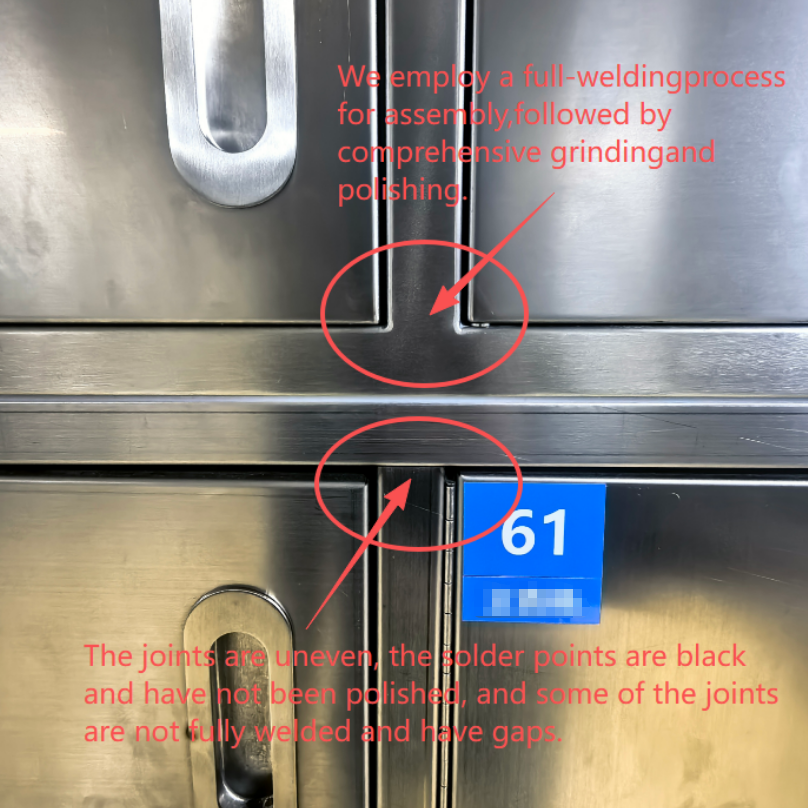

IV. Appearance and Craftsmanship: From "Rough Assembly" to "Seamless Refinement"

Old shoe cabinets had rough craftsmanship: uneven corners, blackened and unpolished welds, and gaps left by unwelded joints. This affected both appearance and structural integrity, done solely to save on labor costs.

We employ a full-welding process for assembly, followed by comprehensive grinding and polishing. Precise corner alignment ensures a seamless and refined appearance. While this increases labor and time, it balances aesthetics and structural stability, resulting in visible quality.

Quality Upgrade: More Than Just Appearance, It's About Craftsmanship

From the pain points of the old cabinets to a leap in quality, it stems from our unwavering commitment to "details determine quality." All optimizations are based on user needs and food industry standards, showcasing our craftsmanship.

This upgrade of the shoe cabinets for our Sam's Club gummies supplier provides the company with safer and more hygienic hardware, helping to strengthen production management. Good products withstand close scrutiny and create real value.