Recently, TFK Technology officially delivered its 304 stainless steel GMP-certified floor sinks, customized for clients in the pharmaceutical and food industries. This product not only meets the needs of cleanrooms with stringent material standards and a user-friendly structural design, but also boasts a solid foundation of quality thanks to its meticulous craftsmanship with thousands of fully welded joints. It not only strengthens the customer's production compliance defenses and improves operational convenience, but also has won high recognition.

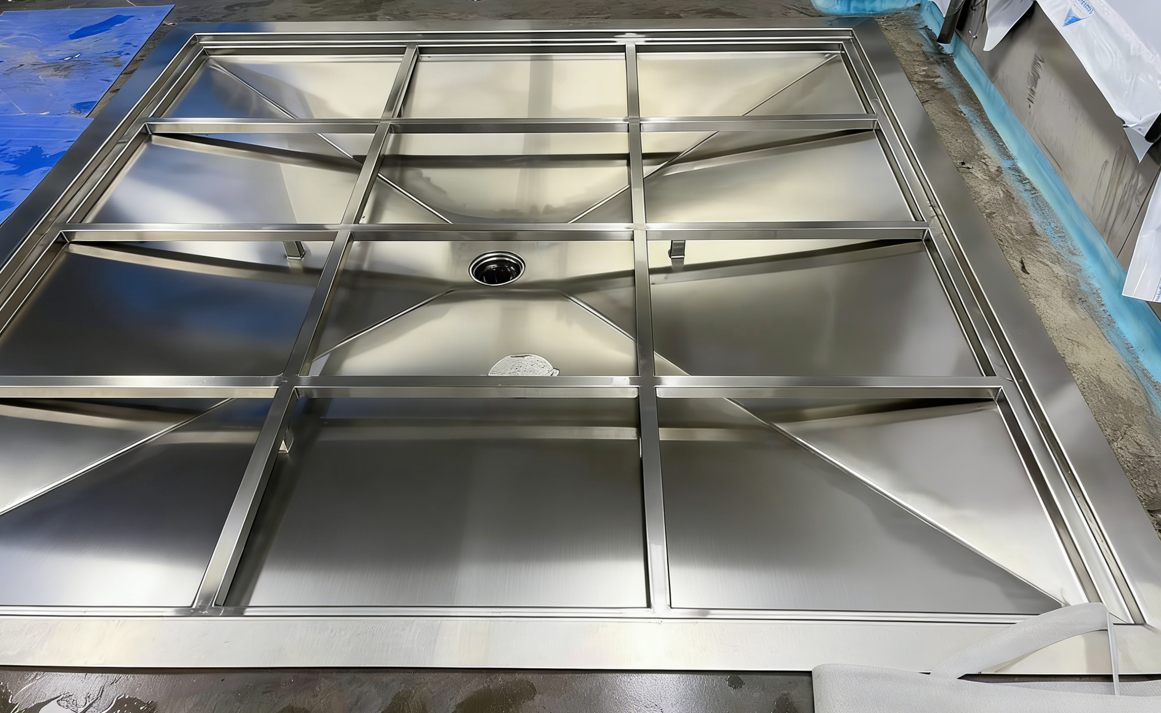

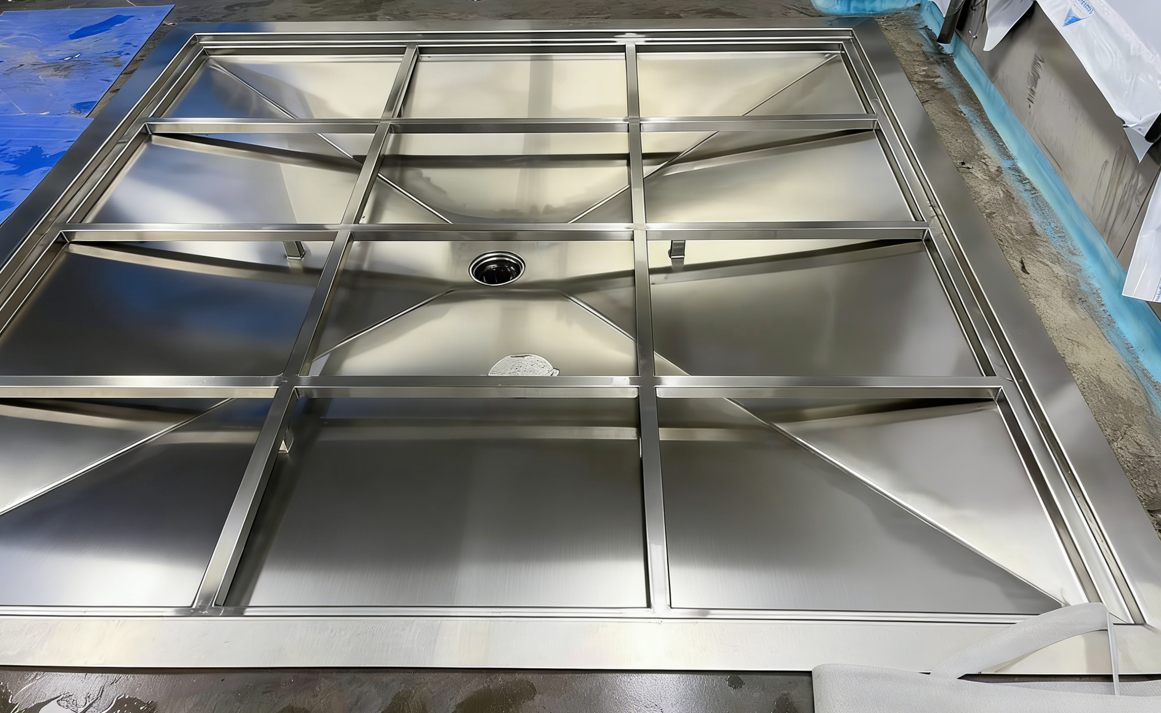

As a core auxiliary equipment in cleanrooms, the material, compliance, and craftsmanship of floor sinks directly affect production safety. The floor sinks delivered this time are made of 304 food-grade stainless steel in a single piece, with a precision brushed surface that is poreless and free of dead corners. They possess excellent rust resistance and acid and alkali resistance, and can withstand repeated wiping and disinfection with commonly used cleanroom reagents such as alcohol and chlorine-containing disinfectants. The products are developed and manufactured in accordance with GMP (Good Manufacturing Practice) standards throughout the entire process. All indicators have passed authoritative testing and certification, fully meeting the stringent compliance requirements of the pharmaceutical and food industries for production auxiliary equipment, thus mitigating contamination risks from the source.

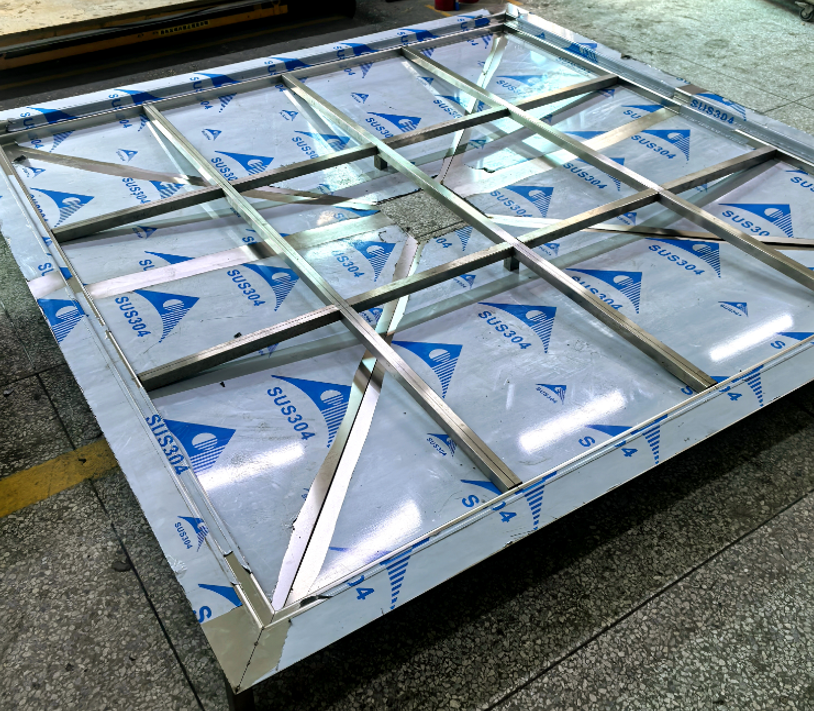

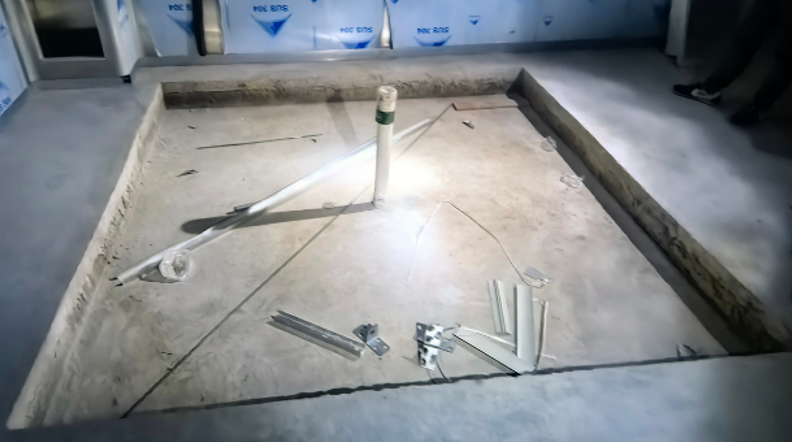

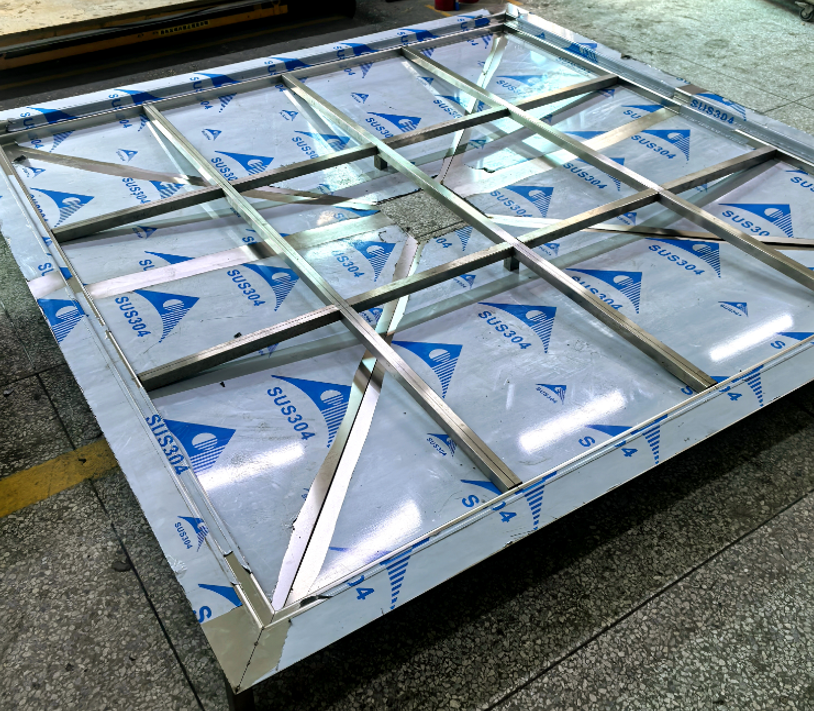

In terms of manufacturing processes, the products showcase TFK Technology's dedication to craftsmanship: to ensure the floor sinks are structurally stable and leak-proof, a full-welding process is used throughout. A single product contains thousands of weld joints, each meticulously hand-welded by professional technicians to eliminate issues of incomplete or missing welds. The entire production process involves more than 30 workers, with labor costs alone reaching approximately 9,000 RMB. This advanced process ensures that the floor sinks maintain structural stability under long-term load-bearing and frequent cleaning conditions, without deformation or leakage risks, perfectly matching the high-intensity usage requirements of cleanrooms.

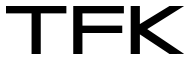

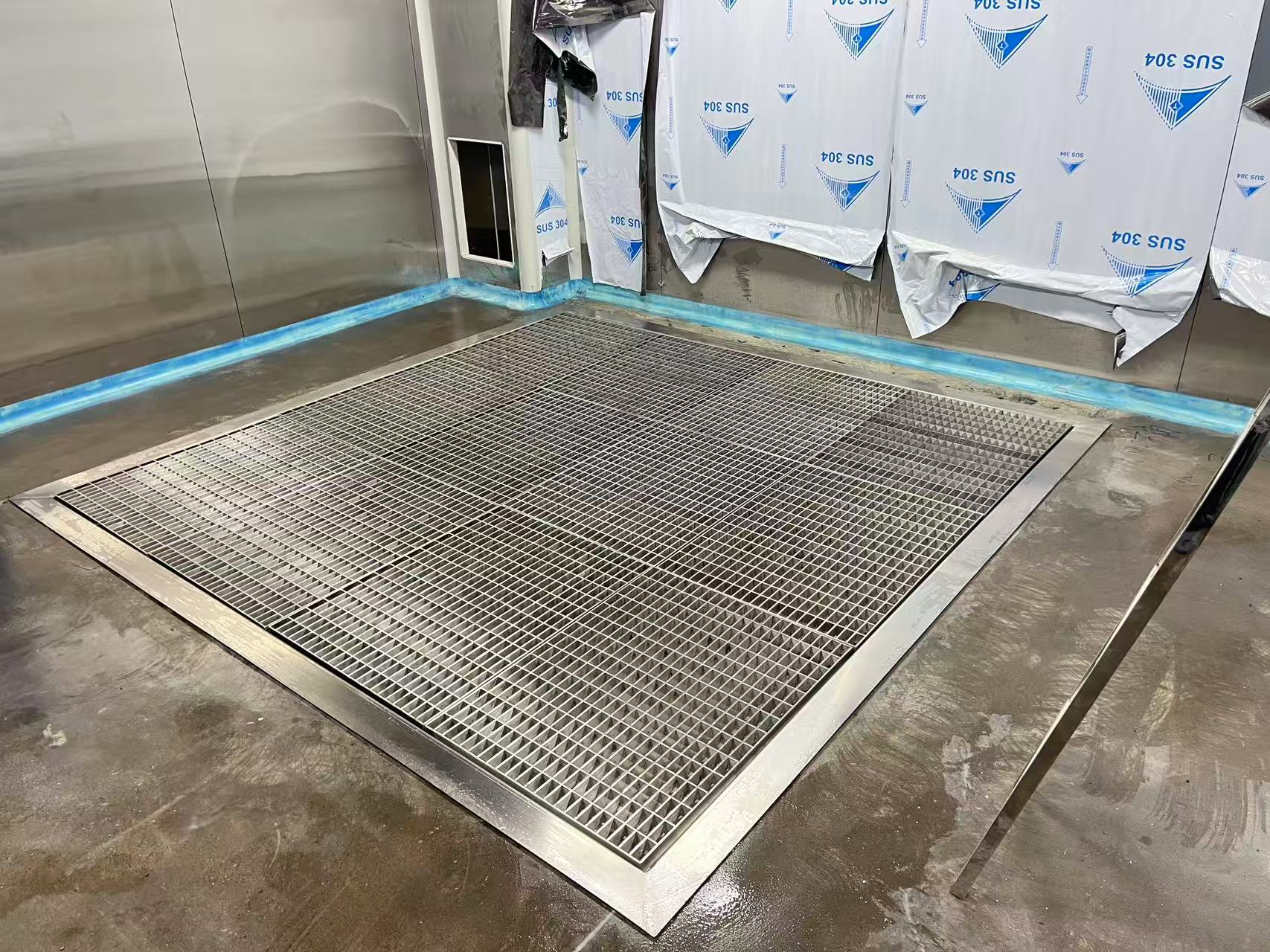

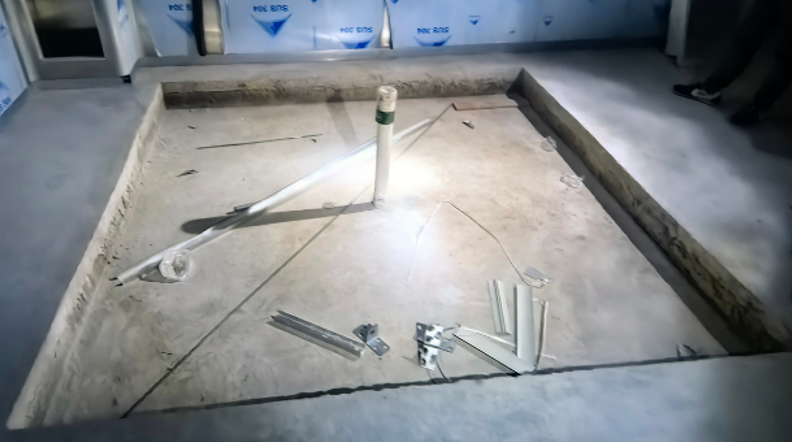

In terms of structural design, the products are deeply tailored to the actual needs of customers, achieving a dual breakthrough in "convenience + practicality." Firstly, the flush design of the floor sink is a key highlight: eliminating the handling difficulties caused by the height difference of traditional floor sinks, staff can directly and smoothly push trolleys and heavy production tools to be cleaned onto the floor sink surface without the need for strenuous lifting, greatly reducing the labor intensity of handling heavy objects and cleaning, especially suitable for batch cleaning scenarios, and improving work efficiency; secondly, the mesh drainage hole structure optimizes drainage performance: the high-density mesh design increases the drainage contact area, ensuring that cleaning wastewater is discharged quickly, preventing water accumulation on the ground and the growth of bacteria, while effectively intercepting impurities and preventing drainage pipe blockage; thirdly, the detachable design simplifies the cleaning process: the floor sink components support quick disassembly, allowing staff to thoroughly clean and disinfect gaps and drainage channels, completely removing residual stains and microorganisms, maintaining the cleanliness of the equipment, and meeting the continuous cleanliness requirements of GMP.

“These floor sinks perfectly suit our workshop's needs. The flush design makes moving heavy-duty trolleys effortless, the mesh drainage holes ensure fast and clean drainage, and the detachable structure simplifies daily cleaning. Plus, the solid feel of the fully welded construction gives them a sense of security,” said the client's production manager. He added that the product's compliance, practicality, and craftsmanship exceeded expectations, providing strong support for cleanroom production.

TFK Technology consistently focuses on the needs of the cleanroom industry, using 304 stainless steel as its core material, deeply cultivating GMP-compliant product development, and adhering to a production philosophy of “meticulous craftsmanship.” The successful delivery of these floor sinks is another example of the brand's “customer-centric, quality-focused” philosophy. In the future, TFK Technology will continue to optimize its product structure and production processes, providing more customized solutions to create more compliant, efficient, and durable production support equipment for clients in the pharmaceutical, food, and other industries.