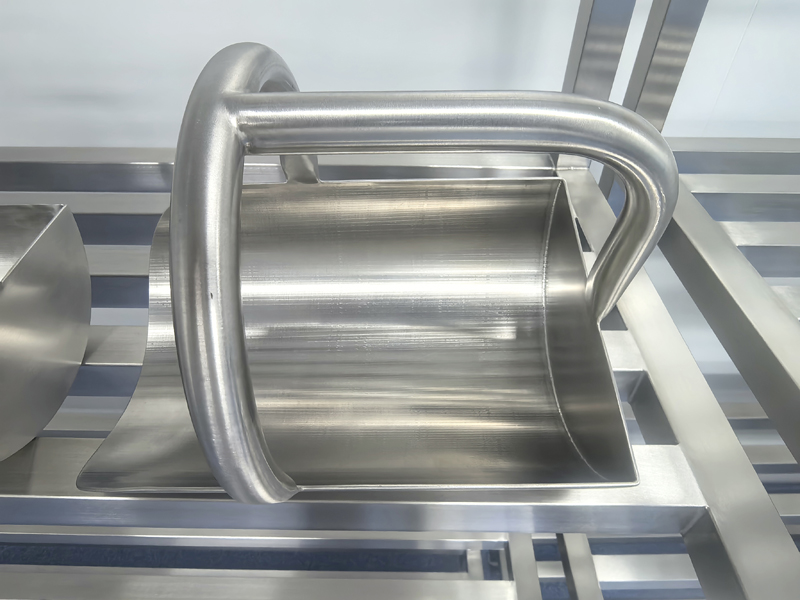

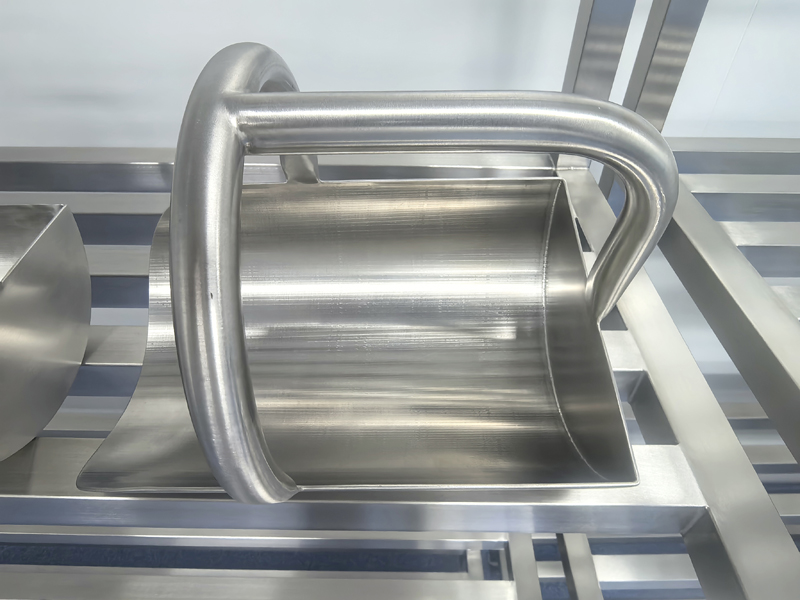

In clinical and clean-room settings, minimizing contamination risks is paramount and closely tied to the structural quality of laboratory furniture. Cabinets produced by leading stainless steel lab furniture manufacturers emphasize smooth welded joints and meticulously sealed frames, which collectively limit areas where dust, microbes, or chemical residues could accumulate. The absence of crevices and gaps not only simplifies cleaning protocols but also aligns with rigorous hygiene and GMP certification requirements pervasive in medical environments. A brushed finish enhances corrosion resistance and aesthetic consistency, reassuring users of both durability and compliance with cleanliness standards. The one-piece sloped roof design commonly incorporated in these models further exemplifies attention to contamination control, reducing dust settlement and easing routine maintenance. This precision engineering allows for sustained sterility within the storage units, thereby supporting critical sterilization workflows. For clinical engineering teams and clean-room planners, such features confirm that the furniture contributes directly to maintaining a contamination-controlled environment. Ultimately, this thoughtful construction translates into a dependable asset that upholds the integrity of stored instruments and the safety of everyone relying on them.

Optimizing laboratory furniture to integrate security, flexibility, and hygienic design sets a foundation for efficient medical and research environments. With tempered glass doors guarded by reliable locking systems, adjustable shelves accommodating diverse storage demands, and careful structural details that limit contamination, these solutions embody a well-rounded approach. Selecting equipment from experienced stainless steel lab furniture manufacturers often ensures these qualities are seamlessly realized in everyday practice. As clinical spaces continue to evolve, furniture that consistently supports operational needs while promoting cleanliness and protection will remain integral. Engaging with these thoughtfully engineered products invites exploration into how tailored design can quietly transform workflow efficiency and security, preparing facilities for the precise demands of tomorrow’s healthcare challenges.