Export Triple-Protection Packaging: Pearl Cotton Wrapping + Transparent Film for Dust Protection + Plywood Frame for Secure Delivery – Stable and Impact-Proof Transport, No Deformation, Worry-Free Delivery.

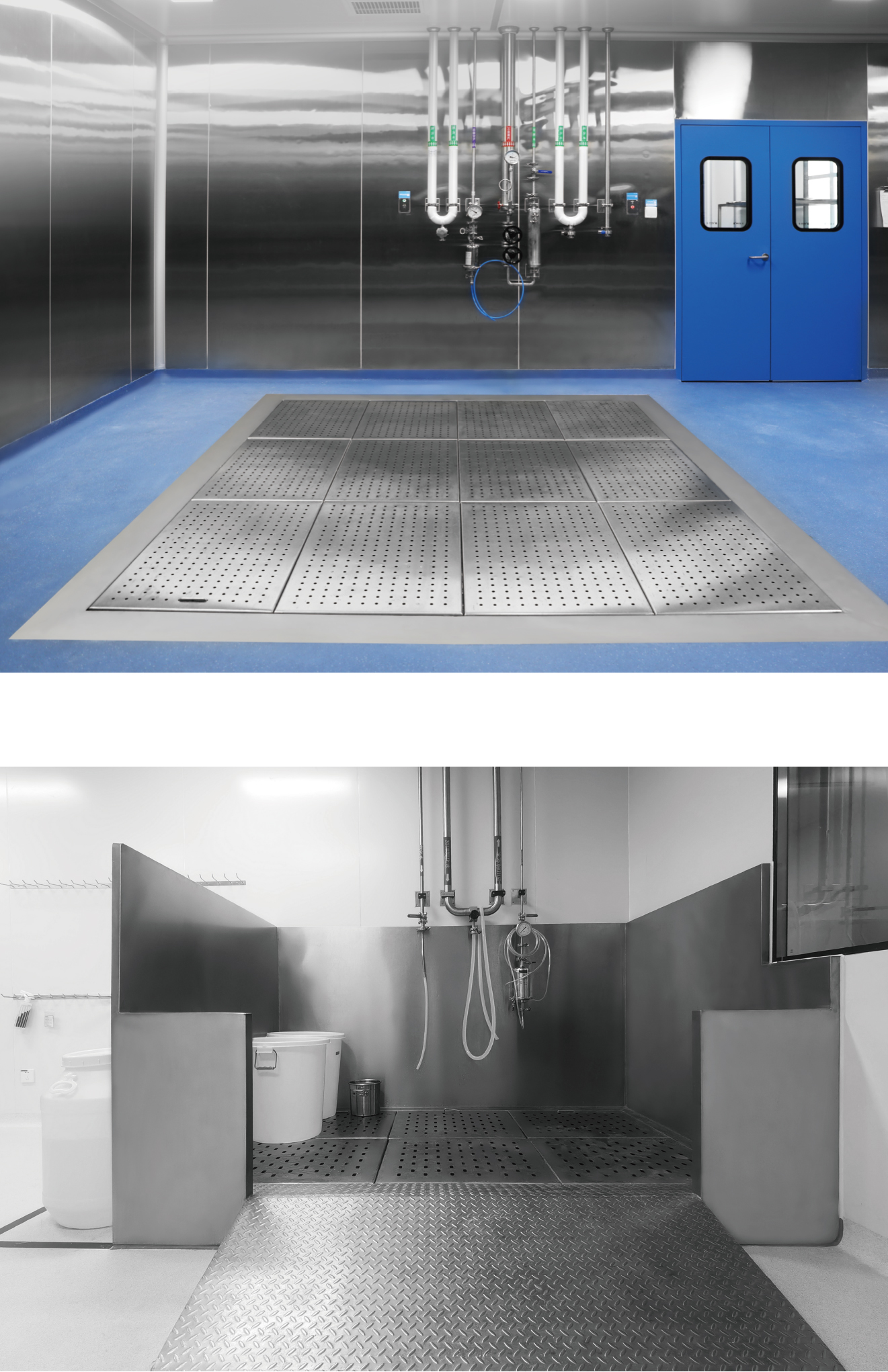

1. The ground pool is flush with the ground, making it easy to access heavy items.

This stainless steel floor-standing sink is specifically designed for heavy-duty cleaning and material transfer in GMP-certified environments. Its integrated structure, with the bottom flush with the ground, addresses the key needs of "efficiency and ease of operation in heavy-duty handling." The sink bottom is directly flush with the ground, eliminating height differences. When moving heavy materials (such as large barrels of raw materials, equipment parts, and batches of experimental equipment), they can be directly pushed or dragged into the sink without lifting or carrying, significantly reducing the labor intensity of operators and avoiding damage and safety hazards caused by bumps and knocks. Simultaneously, the flush design creates a seamless transition between the sink and the ground, eliminating hard-to-clean areas. Cleaning can be done directly with a mop or high-pressure water gun, and wastewater naturally flows into the sink's drainage system, preventing residual stains and water accumulation on the ground. It fully meets the stringent GMP requirements for ease of operation and environmental cleanliness, making it suitable for high-frequency heavy-duty handling scenarios such as pharmaceutical workshops, food processing workshops, and laboratories.

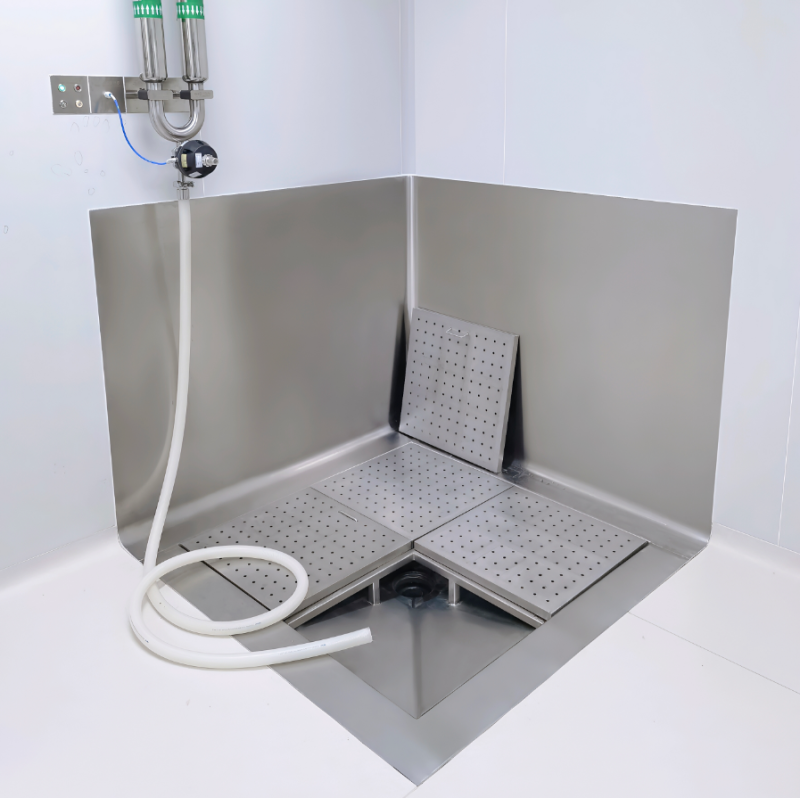

2. A variety of drainage holes ensures quick drainage without water accumulation, and the removable design allows for easy cleaning.

The sink features multiple sets of high-density drainage holes and a removable drainage assembly, doubly optimizing drainage efficiency and ease of cleaning, precisely meeting the core GMP requirements of "no water accumulation and easy cleaning." The drainage holes are designed with a uniform distribution principle; the hole diameter and distribution density have been calculated using fluid dynamics to quickly drain cleaning wastewater and material residue from the sink, avoiding the risk of bacterial growth and contamination caused by water accumulation. This is especially suitable for batch cleaning and high-frequency usage scenarios. The drainage assembly (filter screen, drain core) features a removable design, allowing for easy disassembly without tools, facilitating thorough removal of trapped debris and residue, and preventing clogging. The assembly surface is polished, non-porous, and does not absorb stains, allowing for direct reinstallation after cleaning, making operation convenient and efficient. Simultaneously, the edges of the drainage holes are smoothly polished, without sharp burrs, preventing scratches to operators and materials, and meeting GMP certification standards for equipment corner safety and no contaminant leaching.

3. The wall and floor are welded together with a circular arc transition between the stainless steel plates, eliminating the risk of leaks and water accumulation.

The sink walls and bottom utilize CNC seamless welding and a circular arc transition process, completely resolving the industry pain points of leaks and water accumulation in traditional spliced sinks. This fully meets GMP certification requirements for equipment sealing and the absence of unsanitary corners. The connections between the stainless steel plates employ argon arc welding for seamless welding. The welds are inspected for flaws, showing no cracks or pinholes, ensuring excellent sealing and eliminating the risk of leaks. Simultaneously, the transitions between the walls and bottom, and between walls themselves, all feature a circular arc design with a radius of ≥10mm, seamlessly integrated without sharp edges. This prevents liquid residue buildup (wastewater can be quickly guided to the drain along the arc surface) and eliminates cleaning blind spots—whether it's high-pressure water jet washing, sponge wiping, or chemical disinfection, it can reach every corner, easily removing stains and residues and preventing bacterial growth. The welded joints are finely polished, resulting in a smooth, mirror-like surface that seamlessly integrates with the tank body, eliminating any points of contaminant adhesion and meeting GMP certification requirements for both structural cleanliness and ease of cleaning.

4. The funnel-shaped base allows for rapid drainage, and the bottom is equipped with an odor-resistant floor drain to isolate exhaust fumes.

The innovative funnel-shaped flow-gathering structure at the bottom of the tank, combined with a built-in odor-proof floor drain, achieves the dual functions of "rapid drainage + exhaust gas isolation," perfectly meeting the cleanliness and environmental requirements of GMP environments. The funnel-shaped base, with its naturally converging angle, utilizes gravity to guide wastewater towards the center, accelerating drainage and further preventing water accumulation. The center of the base and multiple drainage holes form a three-dimensional drainage system, ensuring no water accumulation dead spots within the tank. The built-in odor-proof floor drain at the bottom employs a water-seal design, using water to isolate sewer exhaust fumes, odors, and insects, effectively preventing backflow of exhaust fumes and contamination of the clean environment. This is particularly suitable for scenarios with extremely high air quality requirements, such as pharmaceutical workshops and sterile laboratories. The odor-proof floor drain also features a detachable design for easy regular cleaning and maintenance, eliminating any unsanitary corners. Made of the same 304 stainless steel as the sink (316L customization available), it boasts strong corrosion resistance, is rust-free and does not deteriorate, meeting GMP certification requirements for equipment material safety and environmental friendliness.

5. Size can be customized.

Standardized and efficient customization process: Requirements communication → Parameter confirmation → Drawing design → Sample verification (optional) → Mass production → Finished product testing → Delivery and use, with full technical support provided throughout. All customized products use 304 stainless steel as the base material (316L material upgrade available). The production process strictly adheres to GMP standards, ensuring a structure with no unsanitary corners, a smooth and easy-to-clean surface, and dimensional accuracy ≤ ±1mm. Sealing, drainage efficiency, and odor-proof performance undergo multiple tests to ensure safe and compliant use.

Export Triple-Protection Packaging: Pearl Cotton Wrapping + Transparent Film for Dust Protection + Plywood Frame for Secure Delivery – Stable and Impact-Proof Transport, No Deformation, Worry-Free Delivery.

Comments from our customers